How to post-process your 3D prints in 15 minutes with XTC-3D

Problem

You finished a long 3D print and the result is not exactly what you wanted. Your printer is not perfectly calibrated, there are a lot of vibration lines and it bothers you.

Or, the filament colour is a bit off for the project you had in mind.

In either case, you don't want to waste more filament to get the same result or worse.

You decide that you want to post-process your part. But, you don’t have all the time in the world, nor all the money to spend on fixing an imperfect print. You are looking for a fast, easy and cheap way of post-processing your part to perfection.

Solution

We have a quick fix for you and it comes in the form of XTC-3D. A simple and effective way to make the layers disappear or at least, a lot less visible than before.

It is simple, as you only need to mix 2 liquids together and apply it on the part.

XTC-3D is something like epoxy coating for many material types, whether it be from FDM, SLA or SLS printers. At Voxel Factory, we covered parts made from PLA, Formlabs Standard Resin, Carbon Fiber, Woodfill, Bronzefill, Bamboofill and Glowfill.

What's in the Box

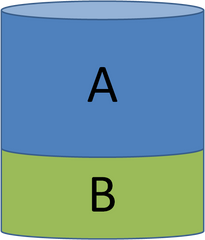

Bottle A, Bottle B, wooden stick, brush, cup and instructions.

How-to use XTC-3D

Step 0: Read the instructions

Obvious.

Step 1: Intensely shake Bottle B

Bottle B contains a hardener liquid and thus needs to be properly shaken before mixing.

Step 2: Pour Bottle A and Bottle B in the measuring cup at a ratio of 2:1

There needs to be twice as much of liquid A than liquid B.

At first, you might not know how much liquid you need. 1 oz of the mixture can cover up to 100 square inches. Unless you have a huge part, 1 oz should be good enough to start. If ever you need more, make more.

Step 3: Mix vigorously for 1 minute

Take the wooden stick and mix it up. Make sure to scrape the bottom and the sides of the cup.

Important side note: mixed XTC-3D is exothermic. While mixing, heat will be generated . Make sure not to mix large quantities in plastic containers as it might melt it. Also make sure not to make skin contact or be close to combustible materials while hot.

Step 4: Apply the coating on the printed part

If the part is small, using the plastic cup should give more than enough time to get your coating done.

If you worry that the mixture will dry up before coating your piece, you can pour the mixture on a flat surface. This will spread the concentrated mass and increase your working time. Smooth-On recommends making a platter from aluminum foil and pour the mixed XTC-3D in it.

Use a disposable brush that you do not care too much about since it will be unusable afterwards. Paint over the piece by spreading the mixture printed part.

Step 5: Let it cure

You can let it cure (“dry”) at room temperature for 2 hours (73°F/23°C). Or, you can cure it faster by putting the piece in mild heat (150° F/60° C) for 15 minutes. Once cured, your part will have a smooth glossy finish.

Optional steps

You can sand and/or paint the coating for different types of finishes.

Sand the part with 220 sand paper for a matte finish and to get rid of small imperfections or excess coating. Make sure not to breathe in the dust while sanding. Wearing a mask is not a bad idea. Once sanded, it will also be easier to paint the piece.

You can first put a primer or go ahead and paint the piece with acrylic enamel paints.

Also possible to mix in fillings or colours to the mixture before applying to have fancy results.

XTC-3D is a simple solution (pun intended) to post-process 3D printed parts to have a glossy or matte finish.

Here are some parts that we covered with XTC-3D

- Tags: 3D Printing Tools Voxel Factory

- Nathan Orfin